Ingenious Polymers: Revolutionizing Modern Production

Making The Most Of the Possible of Polymers: Discover the Diverse Advantages and Practical Uses

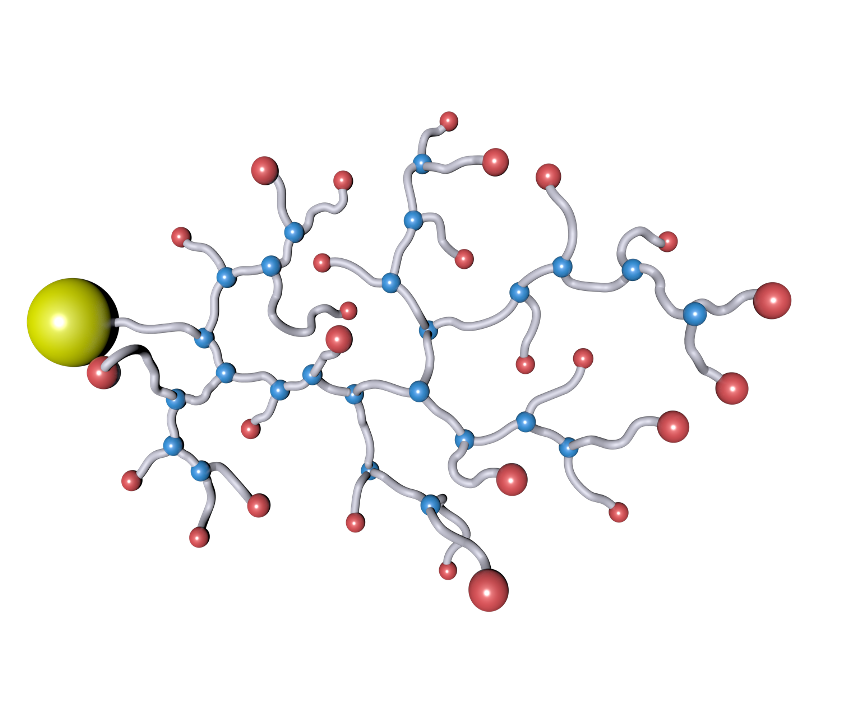

The complex benefits and useful uses of polymers continue to advance, supplying innovative options to intricate challenges. By checking out exactly how polymers can enhance product durability, drive sustainability campaigns, change health care services, and pave the means for future technical innovations, we can discover a world of possibilities waiting to be used.

Importance of Polymers in Modern Industries

Polymers play a pivotal function in contemporary sectors, serving as versatile products that drive advancement and performance throughout a wide variety of sectors. The electronic devices sector benefits from the protecting residential or commercial properties of polymers, vital for producing circuit boards and digital devices. Their adaptability, toughness, and cost-effectiveness make polymers vital in modern production procedures, fostering innovations and driving progress in various markets worldwide.

Enhancing Item Toughness With Polymers

With a focus on long life and resilience, integrating sophisticated polymer modern technologies right into item layout has come to be a keystone of boosting longevity in contemporary manufacturing procedures. Polymers use a wide variety of properties that add to the total sturdiness of items. One vital benefit is their resistance to corrosion, chemicals, and weathering, making them excellent for use in different markets where exposure to rough problems prevails.

Additionally, polymers can be customized to fulfill specific resilience needs, permitting manufacturers to tailor products according to their planned usage and anticipated life-span. By including polymers into product parts, producers can improve toughness and effect resistance, minimizing the chance of damage or put on with time.

Additionally, polymers are light-weight yet tough, giving resilience without including unneeded weight to items. This characteristic is particularly beneficial in industries such as aerospace and auto, where light-weight materials are crucial for boosting gas effectiveness and general efficiency.

Sustainability Improvements With Polymer Technology

In the world of contemporary production and product design, the cutting-edge application of polymers is driving substantial developments in sustainability methods. Polymer development plays an important role in improving sustainability by providing solutions that lower environmental impact throughout numerous industries.

Furthermore, advancements in polymer innovation have actually caused the development of bio-based and eco-friendly polymers, stemmed from all-natural sources such as plants, that use an even more sustainable alternative to conventional petroleum-based plastics. These environmentally friendly polymers not just help reduce reliance on nonrenewable fuel sources yet also lower greenhouse gas emissions throughout manufacturing. By integrating these ingenious polymers right into making procedures, companies can decrease their environmental footprint and relocate in the direction of more lasting techniques, straightening with international initiatives to combat environment adjustment and advertise a round economic situation.

Polymers in Health Care: Revolutionizing Medical Solutions

Among the essential areas where polymers are making considerable strides remains in the growth of targeted medication shipment systems. By encapsulating medications within polymeric nanoparticles or micelles, researchers can enhance medicine stability, enhance bioavailability, and make it possible for controlled launch, bring about extra effective therapy routines with lowered side results.

Moreover, polymers contribute in the area of regenerative medication, where they helpful site are used to develop scaffolds that simulate the extracellular matrix, providing assistance for cell development and cells regrowth. This modern technology holds enormous guarantee for repairing damaged body organs, promoting wound recovery, and advancing individualized medicine techniques.

In significance, the integration of polymers in medical care is driving technology, improving therapy efficiency, and inevitably improving patient outcomes in ways previously thought unattainable.

Future Applications and Developments in Polymer Technology

Advancing at the forefront of scientific discovery, polymer modern technology continues to pave the way for groundbreaking applications and advancements forming varied sectors. In addition, polymer nanocomposites are enhancing the mechanical and thermal residential or commercial properties of products, leading to stronger and lighter parts in aerospace and automobile industries. Looking ahead, researchers are checking out the potential of shape-memory polymers for applications in robotics and biomedical devices, where materials that can "bear in mind" and return to their initial forms supply interesting possibilities for advancement.

Verdict